Use Esim Or Physical Sim eUICC Importance for IoT Explained

Esim Vodacom Iphone Understanding eUICC and Remote Provisioning

The rise of the Internet of Things (IoT) has significantly transformed various sectors, particularly the commercial panorama. This transformation brings with it a number of connectivity challenges that can hinder the full realization of IoT's potential in industrial functions. These challenges range from network reliability to information safety concerns, and they require a nuanced understanding and revolutionary options.

One distinguished challenge is the sheer scale of gadgets deployed in industrial environments. Many factories and manufacturing facilities are outfitted with a massive number of sensors, machines, and IoT devices. Managing connectivity amidst this vast community turns into a logistical nightmare, as varying information transmission standards and protocols can create compatibility issues. Ensuring that each one devices communicate seamlessly is essential for effective monitoring and management.

Interference is one other critical concern affecting IoT connectivity in industrial purposes. Factories usually contain quite a few electronic units, each emitting radio frequencies. These frequencies can overlap, leading to signal degradation and data loss. This interference can manifest in decreased device responsiveness, hampering operational efficiency. Mitigating this interference is crucial for sustaining sturdy connectivity across the network.

Dual Sim Vs Esim Cellular Connectivity Terms Glossary

Bandwidth limitations pose significant hurdles as properly - Esim Vodacom Sa. Many industrial IoT functions require real-time knowledge transmission, which calls for substantial bandwidth. When the out there bandwidth is inadequate, delays can occur, decreasing the effectiveness of monitoring techniques. To address this, industries should evaluate their present network infrastructure and contemplate upgrading to greater bandwidth options or utilizing edge computing solutions.

Data safety is a paramount concern as industrial IoT networks become more complicated. The proliferation of connected units increases the potential attack surface for cyber threats. Unauthorized access to machinery or delicate data can lead to operational disruption, monetary loss, or security hazards. Implementing robust encryption protocols and access controls is significant to safeguarding the integrity of connected methods.

Moreover, ensuring the reliability of connections in geographically dispersed industrial sites is difficult. Many industrial applications function in distant locations with limited access to traditional network infrastructures. Cellular connections may not provide the necessary reliability, while satellite tv for pc communications can endure from latency. Exploring combined connectivity choices or dedicated networks can present more stability and redundancy.

Can You Use Esim In South Africa Understanding eUICC Functionality Explained

Device administration itself presents additional challenges. As industrial IoT platforms scale, managing gadgets all through their lifecycle, from deployment to decommissioning, becomes complicated. Implementing a centralized device administration protocol can help streamline this course of, enabling simpler updates, diagnostics, and monitoring of linked systems.

The integration of legacy systems with new technologies usually complicates IoT adoption. Many industries still depend on older equipment and protocols, which may be incompatible with fashionable IoT solutions. Bridging this hole requires a thoughtful approach, typically involving the retrofitting of present gear or creating customized interfaces that enable legacy methods to speak with new gadgets.

Can You Use Esim In South Africa Understanding eUICC Functionality

Latency issues also require cautious consideration in industrial environments. Many IoT purposes involve crucial processes where even minor delays can have significant repercussions. For instance, in automated manufacturing, well timed data feeds permit for fast decision-making and adjustments. Ensuring minimal latency via optimized protocols and edge processing can improve operational protocol.

Power reliability is an often-overlooked issue that can have an effect on IoT connectivity. Many gadgets in industrial functions are deployed in hard-to-reach locations, making energy supply inconsistent. The improvement of energy harvesting technologies or using long-lasting battery options may help mitigate these challenges, guaranteeing gadgets stay operational in difficult environments.

User coaching and training are very important elements for overcoming connectivity challenges. Personnel have to be well-versed within the operational features of IoT technologies to maximize their potential. This training helps facilitate smoother integration, better maintenance, and optimized utilization, leading to improved efficiency and productiveness in industrial pop over to this site purposes.

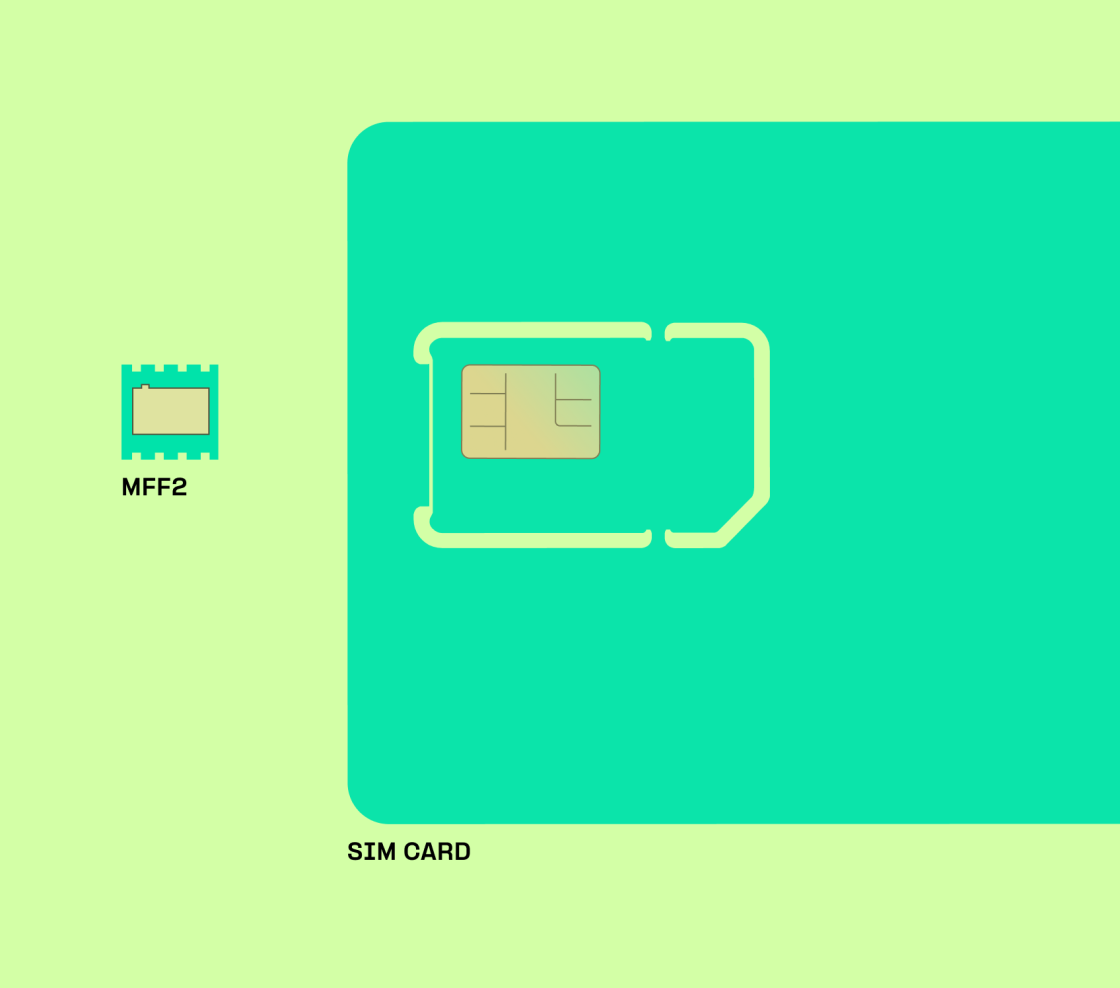

Can You Use Esim In South Africa eSIM vs. IoT SIM Differences

In conclusion, while IoT technologies current exciting opportunities for enhancing industrial purposes, in addition they introduce quite a few connectivity challenges. By addressing points similar to community reliability, information security, bandwidth limitations, and integration with legacy systems, industries can optimize their IoT implementations. Embracing revolutionary solutions and emphasizing consumer coaching may help bridge the gap between present capabilities and future prospects, ultimately leading to more resilient and efficient industrial operations.

- Limited bandwidth in distant areas can hinder real-time data transmission and evaluation in industrial IoT functions.

- The integration of legacy methods with trendy IoT gadgets usually leads to compatibility issues, complicating the implementation process.

- Security vulnerabilities come up from quite a few linked units, growing the danger of cyberattacks in industrial environments.

- Interference from other wireless signals can disrupt IoT communications, leading to unreliable data circulate and operational inefficiencies.

- Energy limitations in edge units can restrict their performance and longevity, necessitating frequent maintenance or alternative.

- Variability in system standards and protocols can complicate system interoperability, decreasing the effectiveness of IoT techniques.

- Scalability can turn into a problem because the variety of related devices increases, overwhelming existing community infrastructures.

- Inconsistent information high quality from diverse sensors may result in faulty decision-making and degraded operational performance.

- Geographic isolation of facilities can limit entry to cloud assets, prompting the need for localized data processing options.

- Environmental elements, similar to extreme temperatures or humidity, can adversely have an effect on sensor performance and connectivity.undefinedWhat are the frequent IoT connectivity challenges in industrial applications?

Common challenges embrace network reliability, information security, interoperability between devices, bandwidth limitations, and latency points. Addressing these requires sturdy infrastructure, effective communication protocols, and layered safety measures.

Esim With Vodacom eUICC Benefits and Applications Explained

How can community reliability impact IoT systems in industries?

Network reliability is essential as interruptions can result in knowledge loss, operational downtime, and increased costs. Ensuring consistent connectivity could be achieved by way of redundant systems, regular maintenance, and utilizing reliable communication technologies.

Esim Vodacom Iphone Choosing eSIM Remote Provisioning Standard

What measures can be taken to boost data safety in IoT applications?

Implementing strong encryption protocols, access controls, and continuous monitoring can improve safety. Regular software updates and worker training on cybersecurity greatest practices are also important in mitigating dangers.

How do bandwidth limitations affect industrial IoT deployments?

Bandwidth limitations can limit knowledge transmission speeds, impacting real-time decision-making and analytics. Solutions embody optimizing data circulate, utilizing edge computing to process knowledge domestically, and choosing applicable IoT communication technologies.

Which Networks Support Esim South Africa eSIM and M2M Consumer Comparison

What position does interoperability play in IoT connectivity challenges?

Interoperability is important as it permits diverse gadgets and methods to work together. Lack of standardization can create silos. Using universal protocols and APIs may help organizations achieve higher integration and functionality across completely different IoT solutions.

How can corporations overcome latency points in IoT applications?

- Esim Vs Normal Sim

Reducing click reference latency may be approached by optimizing community infrastructure, utilizing edge computing to course of information nearer to the source, and deciding on faster communication protocols. These strategies enhance the responsiveness of IoT purposes.

Esim With Vodacom eSIM Meaning for IoT Applications

What is the importance of selecting the proper communication protocol for IoT?

Choosing the proper communication protocol influences data transmission reliability and efficiency. It’s essential to assess the particular use case necessities, such as vary, energy consumption, and data volume, to ensure optimal efficiency.

How can organizations guarantee proper scaling of their IoT systems?

Euicc Vs Esim eUICC/eSIM Solutions for IoT

Proper scaling includes selecting flexible technologies, sustaining a modular architecture, and constantly monitoring system performance to adapt the infrastructure as business needs develop. Regular assessments might help forecast future calls for and prevent bottlenecks.

What ought to firms consider when implementing IoT connectivity in a legacy environment?

When integrating IoT with legacy systems, organizations should consider compatibility, assess potential upgrades to current infrastructure, and guarantee knowledge integration methods are robust. Planning for gradual implementation can even reduce disruptions.